Last

week Intel had their Q1 conference call for financial analysts, and

revealed that the 22-nm Ivy Bridge parts would make up 25% of their

shipment volume in the second quarter of this year. That means

that a good quantity will already will have shipped, and we managed to

track some down in Hong Kong a few weeks ago. Of course we got in

touch ASAP and the parts duly arrived, and they were the real thing.

|

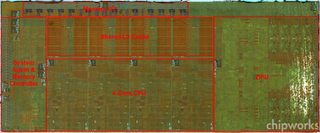

Fig. 1 Intel Xeon E3-1230V2 Server CPU |

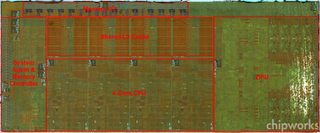

We

obtained samples of Xeon E3-1230 v2 CPUs, which are four-core, 3.3 GHz,

64-bit parts intended for the server market. Here is a die photo of

the transistor level, with annotations from

Intel's Ivy Bridge launch yesterday:

|

Fig.2 Intel Xeon E3-1230V2 Die |

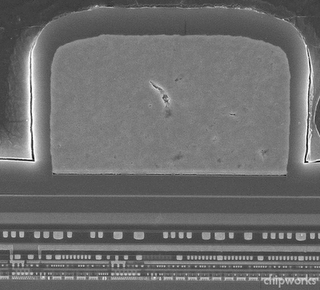

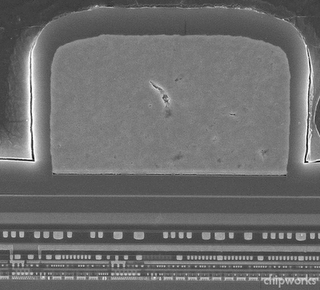

A quick cross-section reveals that Intel have stayed with the nine metal layers used in the last two generations:

|

Fig. 3 Intel Xeon E3-130V2 General Structure |

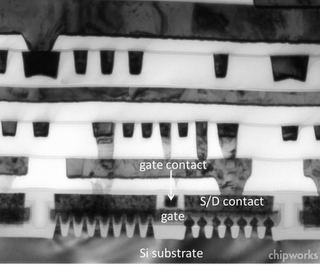

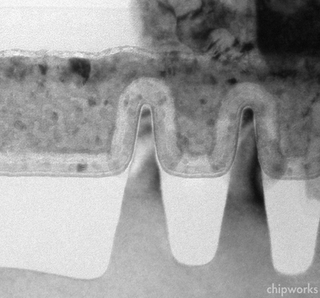

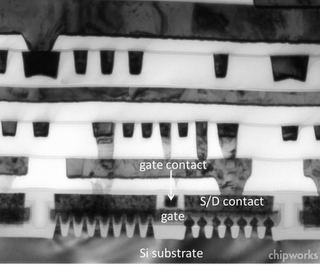

A

closer TEM image (Fig. 4) shows the lower metal stack and a pair of

multi-fin NMOS and PMOS transistors. This section is parallel to the

gate, across the fins, and we can see the contact trenches and metal

levels M1 up to M5.

We have to digress here a little to explain

what we’re looking at. A typical TEM sample is 80 – 100 nm thick,

to be thin enough to be transparent to the electron beam and at the same

time have enough physical rigidity so that it does not bend or fall

apart.

Here we are trying to image structures in a die with a

gate length of less than 30 nm; so if we make a sample parallel to the

gate, and if the sample is aligned perfectly along the centre of the

gate, then it will contain the gate plus at least part of the

source/drain (S/D) silicon and contacts on either side.

|

Fig. 4 TEM Image of Lower Metals and NMOS and PMOS (right) Transistors |

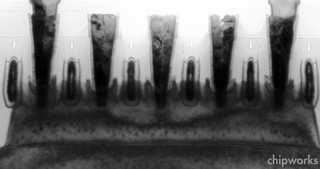

That

is what we see above – I have labeled the gate and contact stripes, and

we have PMOS on the right and NMOS on the left. The

tungsten-filled contacts obscure parts of the gate, but we can clearly

see that the PMOS S/D fins have epitaxial growth on them, and the fins

have an unexpected slope – a little different from Intel’s tri-gate

schematic shown last year –see Fig.5.

|

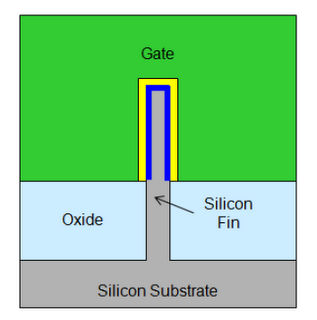

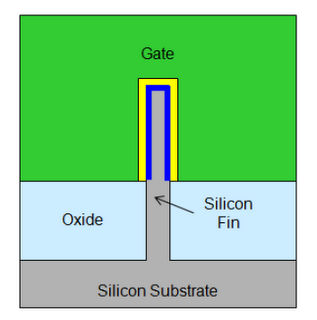

Fig. 5 Intel Schematic of Tri-Gate Transistor |

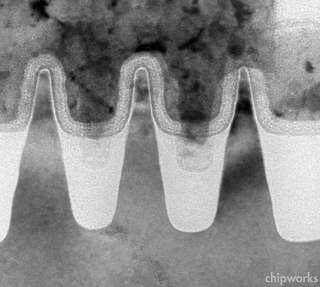

If

we zoom in a bit further into the PMOS gate (Fig. 6), we can see how

the gate wraps over the fin, and the rounded top of the fin. The

thin dark line adjacent to the fin is the high-k layer and just above

that is a mottled TiN layer that is likely the PMOS work-function

material, as in the 32-nm and 45-nm parts.

|

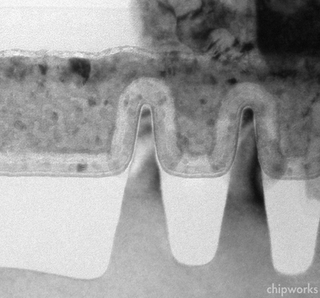

Fig. 6 TEM Image of PMOS Gate and Fin Structure |

Fig.

7 shows a section of an NMOS transistor. There is a ‘ghost’ of

the contact behind the gate, but the gate structure itself looks similar

to the PMOS, with the exception of the work-function material just

above the high-k layer (as expected).

|

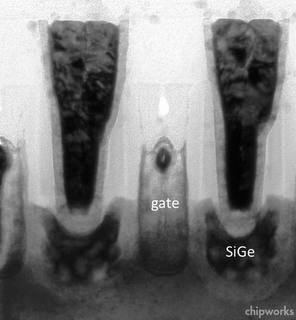

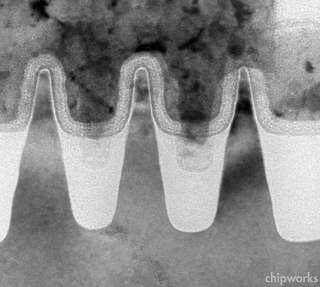

Fig. 7 TEM Image of NMOS Gate and Fin Structure |

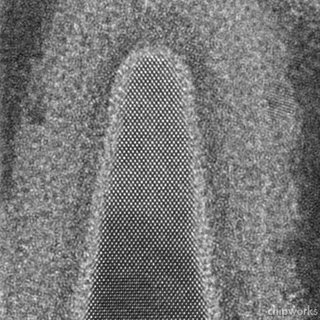

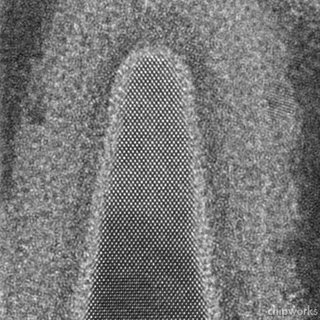

Fig.

8 gives me an opportunity to show off our new TEM – we have recently

purchased an FEI Osiris machine, which upgrades our capability

considerably. Here we have a lattice image of a fin in an NMOS

transistor; the diamond-like layout of the pattern of dots is actually

created by the columns of atoms in the silicon crystal lattice. This

tells us that the sample is oriented in the <110> direction, which

given that silicon has a face-centred cubic structure in which

equivalent planes are at right angles, means that the channel direction

is also <110>.

|

Fig. 8 TEM Lattice Image of NMOS Fin Structure |

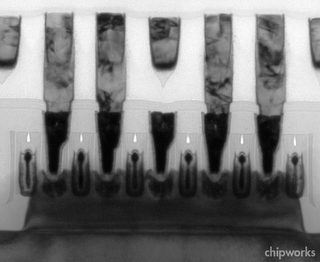

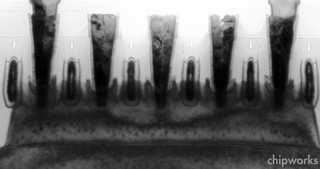

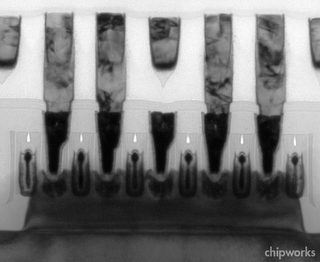

To

fully understand what we’re looking at, of course, we need to see

what’s happening in the orthogonal direction, along the fin and

cross-sectioning the gate – as in Fig. 9. This shows an array of PMOS

transistors over a single fin, four functional gates and two dummy gates

at the ends of the fin. Again the TEM sample is thick compared with the

feature size, so we are seeing the gate on the side(s) of the fin, not

just the top. The fin ends have the same taper as in Figs 6 and 7.

|

Fig. 9 TEM Image of PMOS Transistors |

As

announced by Intel, there is embedded SiGe in the source/drains,

although not etched to the <111> planes as in the 32- and 45-nm

product. It also looks as though the tops of the gates have been etched

back and back-filled with dielectric, and the contacts are self-aligned

as in memory chips.

Zooming in on the PMOS transistor in Fig.10,

the image is a bit fuzzy, but the SiGe is clearly in a rounded cavity

with no facets on the top, though there are facets on the sides of the

fin (see fig. 4).

|

Fig. 10 TEM Image of PMOS Transistor |

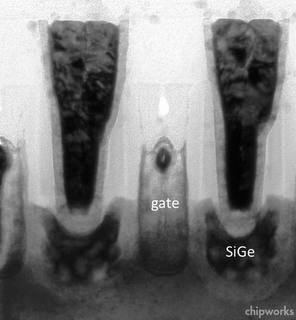

Looking

at the NMOS equivalent (Figs. 11 and 12), we see a similar structure –

there seems to be an epitaxial interface, and the silicide(?) seems to

protrude slightly above the fin.

|

Fig. 11 TEM Image of NMOS Transistors |

|

Fig. 12 TEM Image of NMOS Transistors |

It

is hard to say much about the gates here, either NMOS or PMOS, because

of the sample thickness problem; we are viewing a slice that includes

the gate on both sides of the fin and the fin itself. Fortunately we

have images of gate metal over STI and they are less confusing.

Figure

13 is a composite image of NMOS and PMOS gates so that the differences

are highlighted. The dark line surrounding the gate structures is the

Hf-based high-k, and within that are the two work-function materials,

likely TiN for PMOS and TiAlN for NMOS. (The columnar structure of the

PMOS TiN is visible in the right half of the image.)

|

Fig. 13 Composite TEM Image of NMOS/PMOS Gates |

The

fill has been changed from TiAl in the earlier parts to tungsten. It is

more prominent in the NMOS gates than the PMOS, because the PMOS

structure includes both work-function metals, whereas the TiN has been

etched out of the NMOS gates. At the 45-nm node Intel used tensile

tungsten in the contacts to apply channel stress – have they transposed

this to the gates in the 22-nm process?

Just to finish up, so

that this is still a blog, not a paper (I don’t want to go on too long) –

fig. 14 shows a sample delayered to expose the transistors, and imaged

on a tilt angle. Both the gates and the fins show up nicely, and

we can actually see tiny spikes of SiGe in the PMOS source/drains. The

small pillars in between the fins in the NMOS areas are residual bits of

contact metal. I think it’s a cool image!

|

Fig. 14 Tilt SEM Image of NMOS/PMOS Transistors |

We are just getting into the full scope of the

analysis, so likely more to come in the next few weeks!

I'm still tweeting as @ChipworksDick, for those that way inclined..